REISSER EILERS & PARTNER AG

CONSULTANT FOR FILTRATION AND DRYING TECHNOLOGY

Presentation & History

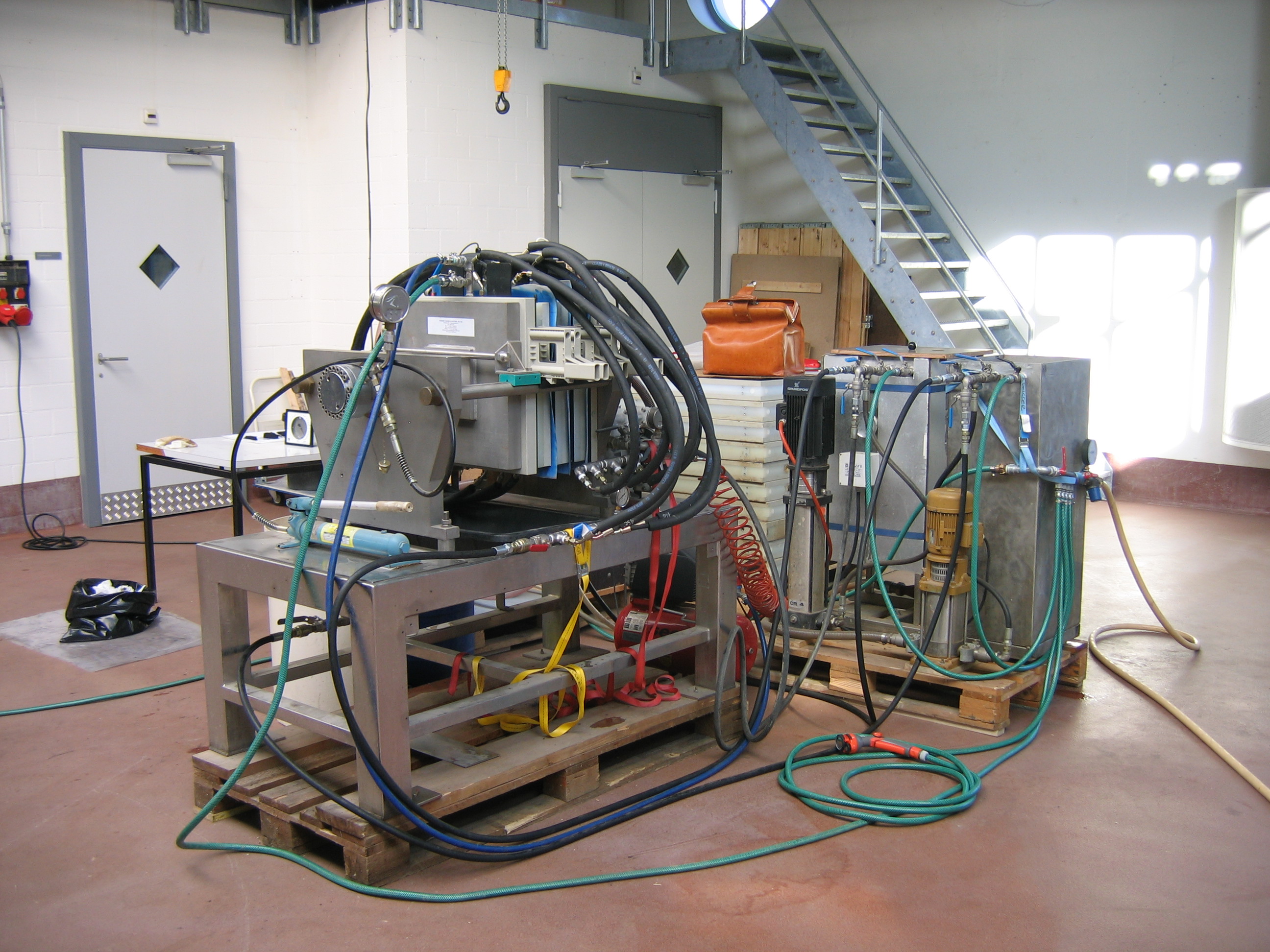

With more than 25 years of experience in solid-liquid separation with hot filter press-ROLLFIT® and condensation drying, we are able to propose a unique and efficient technology to industries and to the environmental company.

The ROLLFIT® technology was developed by Von Roll Filtration division in the first year of 1990, and patented in 1993. In 1997 they sold this technology to Bertrams Dehydrat AG, a member of the Bertrams AG group. In 1999 Reisser Eilers & Partner AG acquired this technology, finished and expanded the development with licence Eurotec, Ltd Tokyo in the Japanese industries.

Since 1997 we have, together with our licences, built more than 30 ROLLFIT® in Europe - Switzerland, Germany, Belgium, and Asia - Japan, China.

Due to the fact that ROLLFIT® is an interesting technology, only if you have at site the necessary energy like hot water at 90°C or steam at 6 bar 158°C and cooling water at 15°C. The maximum size of the filter press must be: membrane plate 1200x1200mm and plate pack 50 to maximum 75.

Due to the fact that the capacity is limited because of the quantity to process, the DS% to have to achieve it would be better to separate the process in filtration first and in drying second. To achieve that we recommend to use automated membrane filters press AF type from Aquachem GmbH and condensations dryer Drymex® from Harter GmbH, both German companies. Both systems with high performance and low energy consumption.